Scriptly Helps Pharmacies Identify Trends in Real Time with Reveal

Accounting for approximately 16% of the global GDP, manufacturing is one of the most important industries in the world’s economy. As such, the need to streamline manufacturing processes is of essential importance. To do that the industry embraces the power of data analytics to ensure improved decision making and enhance performance.

Data analytics offers manufacturers the ability to gather, store, process and utilize data in their daily operations by drawing key insights about improvement and optimization opportunities.

Watch a Demo BOOK A PERSONALIZED DEMO Request a Demo FREE TRIAL

Manufacturing analytics brings predictive analytics, big data, IoT, and mobile-first design to manufacturers so they can ensure quality, optimize performance and yield, reduce costs and improve supply chains. Manufacturing analytics collects, processes and analyzes large amounts of data from numerous sources like machines, orders, delivery, and people. With manufacturing analytics, the data gathered is transformed into easy-to-understand insights that manufacturers can act on in real time.

Market demand is rarely stable, making it harder for manufacturers to forecast the future and address market needs. In the past, demand forecasting relied on the analysis of historical data and experience, but now with the help of predictive analysis, manufacturers can have a clear and comprehensive view of the manufacturer’s processes to effectively identify recurring trends and anomalies in data. That makes it easier to determine what needs to be prioritized and where the focus should be.

Much of the success of a manufacturing company relies on customer satisfaction, so making customers happy is paramount. Today consumers want more personalized and customized products and to be able to keep up and provide such products, manufacturers need data, data, and more data. Data analytics provide them with actionable insights that help them transit from mass production to mass customization where products are personalized to the individual customer or market segment.

Data analytics in manufacturing can reduce costs in many areas such as preventative maintenance to reduce equipment maintenance expenses; lower costs by delivering insights into energy consumption; improved forecasting to reduce inventory levels; and others.

To achieve operational efficiency, manufacturers rely on data analytics to minimize downtime by automating machine’s operations. The use of data analytics also helps manufacturers determine whether a machine is good for work or should it be shut down to prevent the occurrence of any issues.

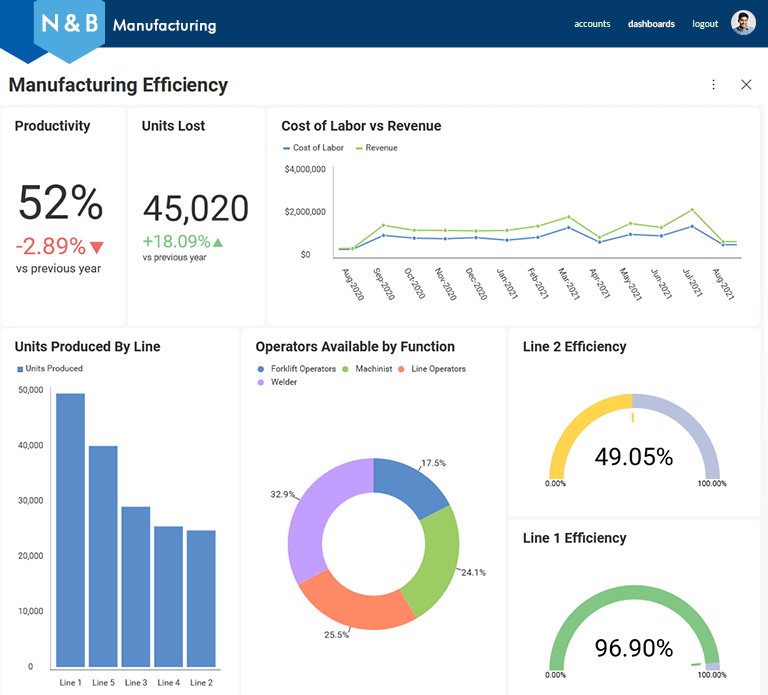

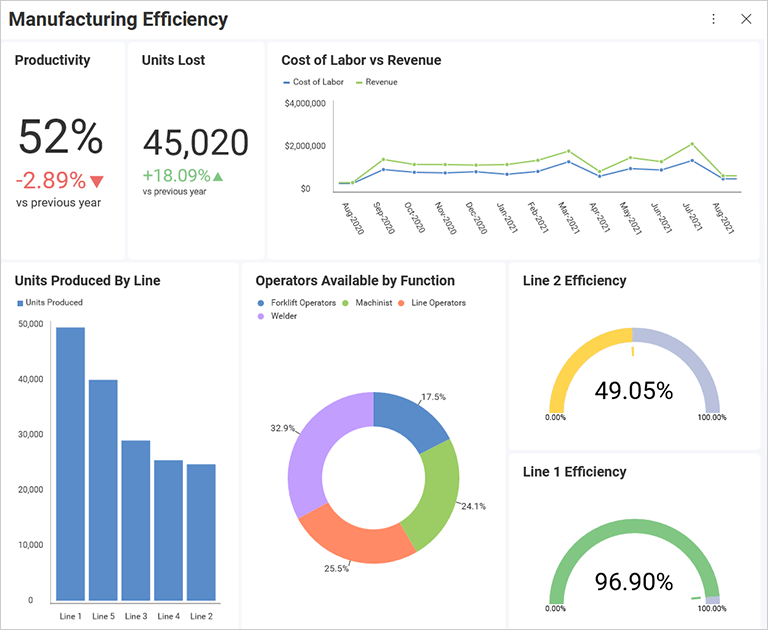

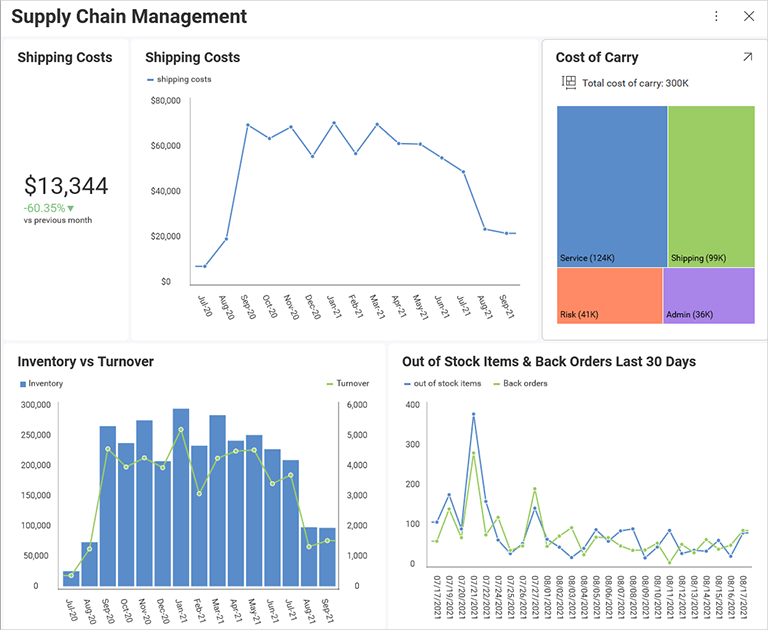

Manufacturing dashboards are used to track and display data from machines, devices, sensors, and employees to gain deeper insights into the company’s overall performance. Visualize and track the entire manufacturing process in real time with these dashboards:

Manufacturing quality dashboard makes quality data easy to access and understand and can help manufacturers make decisions to optimize different processes to ensure top product quality. Quality dashboards provide actionable insights and important metrics that can be suited to the demands of different roles in the manufacturing process. For example, a plant floor manager can focus on the metrics for a specific line and whether it meets forecast production and production standards, etc.

A supply chain dashboard provides supply chain leaders with a great visibility of the supply chain for timely and effective decision making. It tracks inventory levels, logistics management and warehouse operations from a single display that helps identify improvement opportunities.

Embedded manufacturing analytics directly integrates powerful analytics capabilities into the tools and applications organizations use in manufacturing operations.

Embedded analytics plays a critical role in modern manufacturing, enhancing operations from the shop floor to the executive level. As raw materials enter the facility and finish products exit for distribution, these analytics tools help optimize the entire manufacturing process.

Manufacturing analytics software is a management tool that captures and analyzes manufacturing data analytics and provides real-time actionable insights to manufacturers for better decision-making and operations improvement.

Back to Top